Forging Cosmic Patterns for Everyday Design

Reading the Sky in Metal Grains

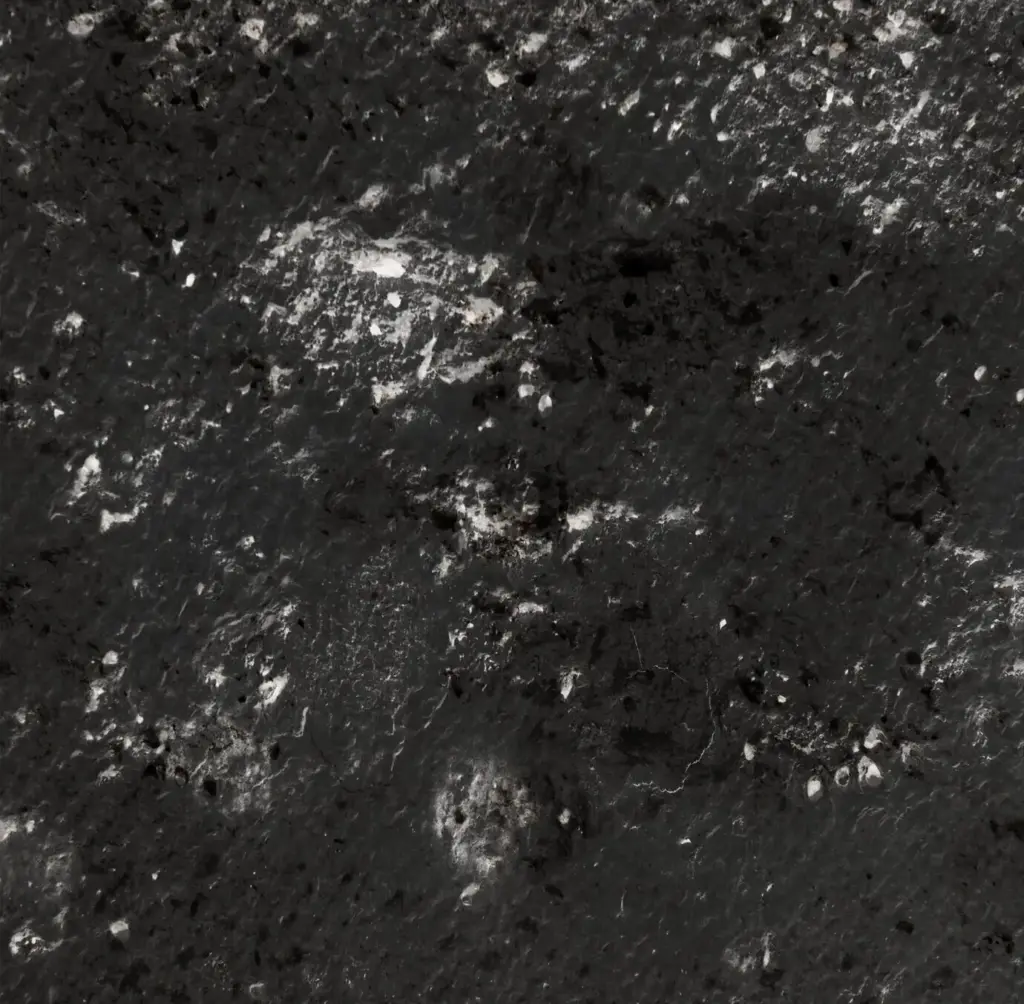

Fusion Crust Drama Without the Heat

Balancing Wonder With Manufacturability

From Cosmic Stones to Store Shelves

Material Choices That Take the Finish Well

Metals That Welcome Etchants and Beams

Aluminum 6061 and 7075 respond beautifully to bead blasting before Type II or Type III anodize, capturing valleys and locking in dyes. 304 stainless takes ferric chloride etch and black oxide for rich contrast. Titanium invites laser texturing plus voltage‑controlled anodizing, achieving iridescent depth while maintaining strength, corrosion resistance, and compelling tactile nuance across wear points.

Polymers That Mold Microtopography Cleanly

Textured steel tooling, EDM spark finishes, and laser‑engraved molds can inject repeatable micro‑pits and ridges into ABS, PC, or TPU. Add subtle dry‑brush paint passes and matte clears, and molded parts gain believable stony complexity with low unit cost. The key is gate placement, draft, and venting to keep those delicate details crisp and consistent.

Abrasive Media, Angles, and Smart Masking

Lasers, Parameters, and Grayscale Maps

Electrochemistry, Photoresists, and Controlled Chaos

Color, Oxidation, and Perceived Depth

Patinas, Washes, and Layered Glints

Start with a dark base—black oxide, manganese phosphate, or charcoal dye—so valleys recede. Add thin metallic washes rubbed across peaks to emphasize structure without filling detail. Finish with satin or soft‑touch clear, adjusting gloss units to manage fingerprints while allowing gentle specular flashes that keep the eye exploring every crater, ridge, and cosmic groove.

Anodizing Tricks for Titanium and Aluminum

Type III anodize on aluminum locks in micro‑relief, drinks dye deeply, and withstands abrasion. Titanium’s voltage‑driven anodizing paints peaks with iridescent blues or golds, shifting with angle. Pre‑texture lightly, then color; final bead blast or tumble softens hot spots, ensuring the finish reads geological rather than decorative, while retaining corrosion resistance and consistent, serviceable maintenance routines.

Vacuum Coatings and Paint-First Alternatives

PVD nitrides deliver durable dark chromes and graphite tones that highlight etched networks, while DLC adds slick resilience. Where cost or throughput matters, basecoat‑paint‑clear stacks emulate depth using metallic pigments and micro‑flake orientations. Pair with laser‑masked accents to reveal raw texture beneath selectively, creating believable stratification that looks engineered yet intriguingly ancient at first glance.

Haptic Metrics That Match the Story

Proving It in the Lab and the Field

Care, Repair, and Aging With Character

Co-create the Next Cosmic Surface

All Rights Reserved.